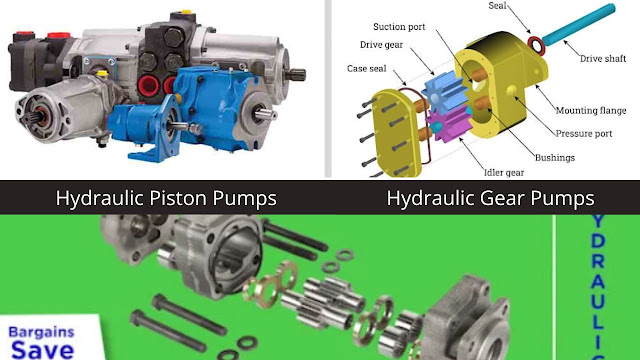

What kind of water hydraulic pump do you want for your expert interaction? Whether driving a business dump truck or working a pass-on press at a modern office, become familiar with the two fundamental sorts of pumps: cylinder and stuff. Think about Hydraulic piston pumps versus pressure-driven gear pumps to see why Panagon Systems represents considerable authority in excellent post-retail piston pumps.

The most Significant Difference:

The two styles of pumps move energy through the pressure-driven liquid to make mechanical power where it's required. A piston pump regularly utilizes responding movement to make a turn along an axis. Some Denison Piston Pumps have variable displacement, while others have a decent displacement plan.

Gear pumps use pinion wheels or machine gear-pieces to move liquids. The machine gear-pieces are firmly adjusted to make attractions as they attract fluid and release it. The cog wheels can be interior or outside, reliant upon their application. They are constantly fixed displacement, so you want separate pumps or valves to manage how much removal.

Unknown Benefits of Piston Pumps vs. Gear Pumps

A hydraulic piston pump is equipped for the most elevated pressure evaluations. Pick a pump series from the cylinder pump line to see the most incredible psi for each pump. Commonly, these hydraulic-powered frameworks can arrive at pressures up to 4,000 psi. This permits you to pump hydraulic liquid at levels fit for fueling rock solid lifts, presses, scoops, and different parts like cat online parts.

Piston-style pumps have complex inner parts that frequently allow them to fluctuate the uprooting per fire. Contrasted with a stuff pump, you have undeniably more control and customization when you pick a Panagon Systems hydraulic-powered Piston pump. The entirety of this intricacy and strain accompanies a higher forthright expense. However, the superior proficiency frequently makes them prominent speculation for long-term production.

Gear pumps typically maximize at 3,000 psi. While this is sufficient strain to control some apparatus, it might not have the essential ability to work the enormous presses and other modern gear. A stuff pump is more reasonable, so you will not need to proceed as much support. Tragically, it might not have the most extreme working strain you want to remain at the bleeding edge of your industry. A stuff style pump can't likewise fluctuate the uprooting of your framework.

Now that you've investigated the benefits of hydraulic-driven cylinder pumps versus hydraulic-powered pumps explore why numerous producers and specialist organizations in your industry pick Panagon Systems for their hydraulic-powered needs.

Substituting the Piston Pumps and Its Parts

After looking at hydraulic piston pumps versus hydraulic gear pumps, it could be clear that you want a piston pump for your specific need. Work with Panagon Systems to arrange a secondary selling pump and to appreciate new parts.

Keep up with Drilling parts determination of parts and request one to fix a Panagon Systems pump or an OEM elective. We cautiously plan and architect the pumps and components instead of OEM parts. Consider one of the new parts for a reasonable, viable, and in-stock answer for a harmed pressure-driven piston pump.

.jpg)

.jpg)

0 Comments